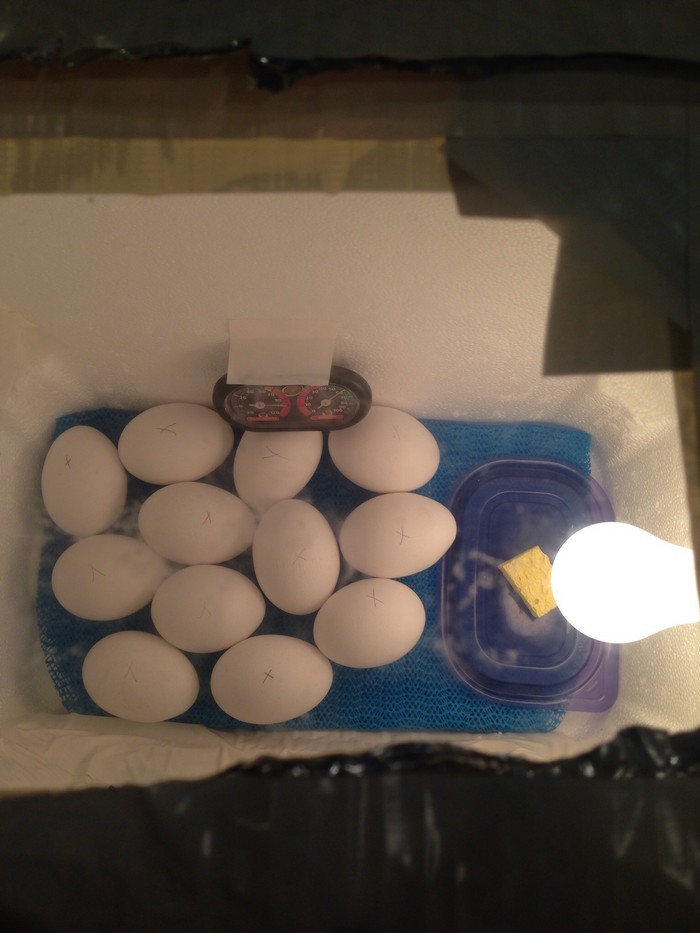

We also needed quite a few sponges to achieve this number. Placing the water sources directly underneath the ceramic lamp increased humidity into an acceptable range (45%-55%). Ideally we wanted something that averaged between 99*F and 100*F, without going above 103*F or below 97*F. We played around A LOT with different incubator layouts and bulb/fan cycles to get the best heat cycles. The platform is made from a cooling rack with that cushy shelf cover underneath it, with a little rim around the edge to prevent eggs or chicks from falling if the incubator gets bumped. We put the eggs on a platform above two bricks.

It's running pretty low, but moves enough air around to speed heating. The fan is just a little plastic fan attached to a 12v motor that is connected to a 5v outlet on the Raspberry Pi. With them just heating the air, they ended up overheating their own component parts and breaking up rapidly. The ones we got were designed to be in a snug fit with some kind of metal to conduct the heat away from the cartridges rapidly. We experimented with using heating cartridges at first, but they got insanely hot and were not appropriate for this purpose. The heat source is a black 100w MAYKEY ceramic heat lamp. Our original lid was just sat flush on the top of the box, but I could feel heat escaping from the sides, so I whacked together a lid that has overhang on each side and drops down into the box to leave fewer gaps between the edges of the insulation. We cut out a gap for the fan and fan motor and drilled some holes for ventilation and wiring. We built the incubator frame with 1/2" plywood and added a single layer of foam insulation to the inside on all surfaces. One of the big benefits of building and programming the incubator ourselves was extreme control and logging of the temperature inside the incubator, and being able to get our temperature swings down to about 1.6* around our 99.5*F target. (Of course, our eggs could fail to develop and then this would be a big failure - but negative results are important too.)

DIY INCUBATOR UPDATE

But I thought I'd share our progress and data, and when we make improvements later this year (potentially for a meat chicken hatch or maybe more layers) will update with more pictures and information. The incubator is a little on the ghetto-fabulous side right now as this is functionally a very expensive prototype.

DIY INCUBATOR PLUS

But he promised that if the incubator failed and killed the eggs, he'd buy me new ones plus a commercial incubator to make up for it. (If you're specifically interested in this code, I'm sure I can get that from him.) We popped a dozen fertilized Black Copper Marans and Azure Egger eggs from Alchemist Farm (in CA) in there this morning. Husband literally programmed a Raspberry Pi to turn a ceramic heat lamp and fan on and off at specific set points to maintain a consistent internal temperature of 99.5*F within the incubator. We didn't just buy a thermostat and hook it up to our heat source and fan to control the temperature. My husband and I decided to dive right into the deep end of egg hatching by building and programming our own incubator for our first hatch.

0 kommentar(er)

0 kommentar(er)